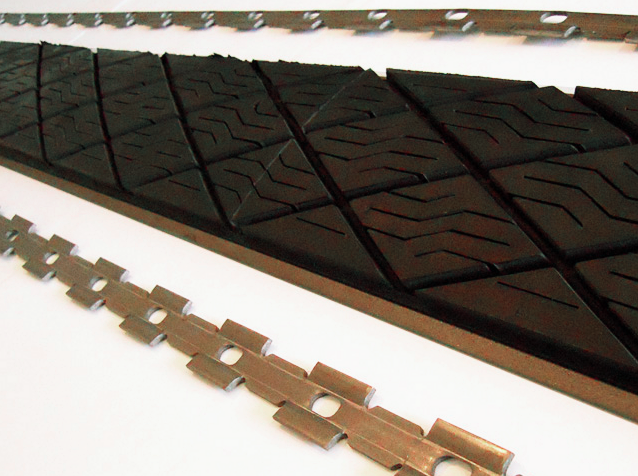

Slide Pulley Lagging

Pulley Lagging act as very important role in a conveyor system,

Preventing rubber conveyor belt from slipping and deviation;

Protect drum surface from corrosion and unnecessary wearing.

Compare with traditional method of drum lagging, no matter hot vulcanized drum lagging or cold bonding drum lagging, advantage of slide drum lagging is very obvious.

Easier to install, easier to change/replacement, lower material cost, shorter down-time...

All these advantages make slide pully lagging is more and more popular.

VSK Slide Pulley Lagging made of super abrasive rubber compound,

Wear resistant rubber compound slide lagging for general purpose are widely used in many tough conditions, such as port, cement industry, steel industry...

Fire resistant rubber compound lagging specially designed for working conditions like coal mining and other underground applications.

Dimensions and value added service:

Slide Pulley Lagging

Install or change without removing pulley

High friction coefficient.

Self cleaning and cooling design.

Weld on and replaceable, easy to intall and change,

Shorten down-time, save the cost in every aspect.

Extend service life of conveyor belt and drum/pulley.

扫描二维码分享到微信